Providing High Performance service for multiple industries And Technologies

Lorem Ipsum is simply dummy text of the printing and typesetting industry. Lorem Ipsum has been the industry's standard dummy text ever since the 1500s, when an unknown printer took a galley of type and scrambled it to make a type specimen book. It has survived not only five centuries

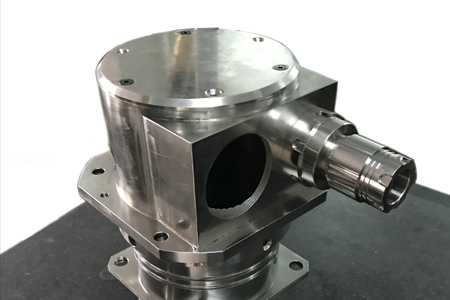

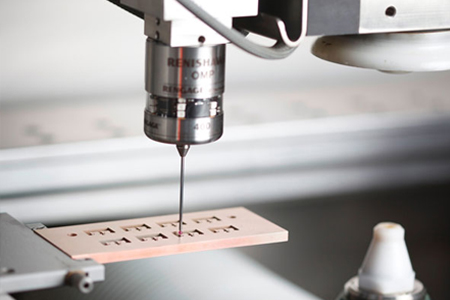

PRECISION MACHINING

precision machining capability from all conventional machining up to 5 axis milling with skilled operators, experienced programers and production engineers handling following materials

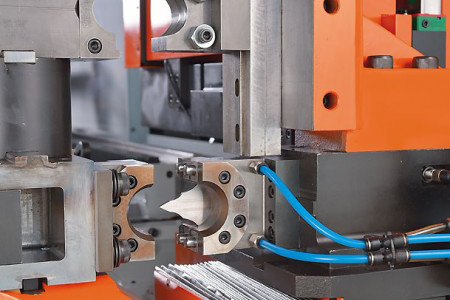

MOULDING AND CASTING

we have tool room facility equipped with highly skilled tool designers, die makers & machine operators with state of art machining facility,capable of manufacturing highly complicated plastic injection moulds, die casting dies, gravity casting dies, rubber moulds and press tools, based on qty and customer requirement.

FORGING AND MACHINING

open/close forging of ferrous and non-ferrous material to minimise cost and increase productivity, we design and manufacture forging dies to suit requirements and forged blocks undergoes various machining operations.

MANUFACTURING ASSEMBLIES

well experienced in manufacturing assemblies production lineup, includes assemblies above 100 parts per assembly, manufactured through different processes like molding, casting and machining.