CAD–CAM–RPT–CAPABILITIES

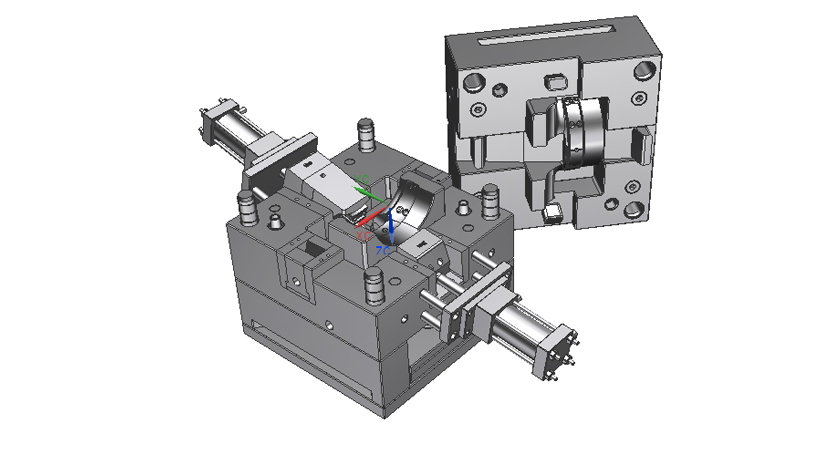

We have well experienced tool designers, CNC programmers equipped with state of art cad cam software’s capable of handling all type of 2D & 3D drawing conversions, 3 axis, 4 axis and 5 axis CNC programming and we have our sister concern facility equipped with FDM machines (plastic 3D printing) to DMLS (metal 3D printing).

CAD–CAM–RPT–CAPABILITIES

- 1 2d drawings to 3d models for manufacturing using high end cad software’s. Conversion of other standards to ISO standards for easy processing.

- 1 Inches to MM

- 1 Russian ghost to ISO

Conversion of point cloud data, co-ordinates data or complex profiles from equations/ expressions to 3d models. Detailed process plan and drafting of detailed 2d drawings for various operations like drilling, boring, turning and spark erosion. Reverse engineering from sample component by CMM, 3d scanning and 3d printed samples for testing before production

CAD–CAM–RPT–CAPABILITIES

- 1 FDM (fused deposition modeling) – abs, pla, pc, nylon (150-200µ)

- 1 SLA (sterio lithography) –acrylic based plastics (25µ)

- 1 SLS (selective lazer sintering) – nylon (100µ)

- 1MJF (multijet fusion) - nylon (100µ)

- 1 DMLS – metal 3d printing (direct metal lazer sintering) ss, maraging steel, aluminium, titanium, inconel

Cobalt chrome (100µ) CNC programming for 2D operations, 3axis, 4 axis and 5 axis 3D programs using high end cam software’s. Design and development of jigs and fixtures for high productivity with repeatability, quality and assures fool proofing.